Blog

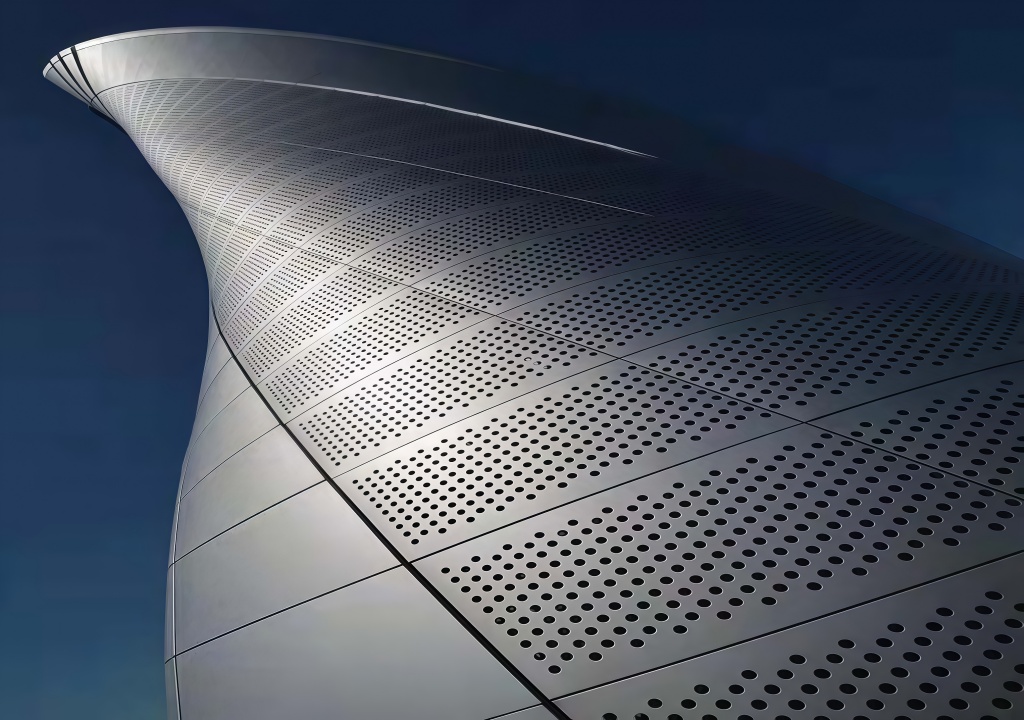

Double-Curved Aluminum Panels for Facades | 2.5mm PVDF | SEA Projects

Double-curved aluminum panels are a popular choice for modern facade architecture where designers want smooth, flowing surfaces and a high-end finish. For projects in Malaysia and Singapore, a durable coating and stable fabrication quality are key to long-term performance in humid, coastal, and high-UV environments.

At ZOLON Aluminium, we supply double-curved aluminum panels made from 2.5mm aluminum with PVDF coating, and we support the full project process—from shop drawings & detailing to installation system solutions—to help contractors and facade consultants deliver complex curved elevations efficiently.

Section 1: What are double-curved aluminum panels?

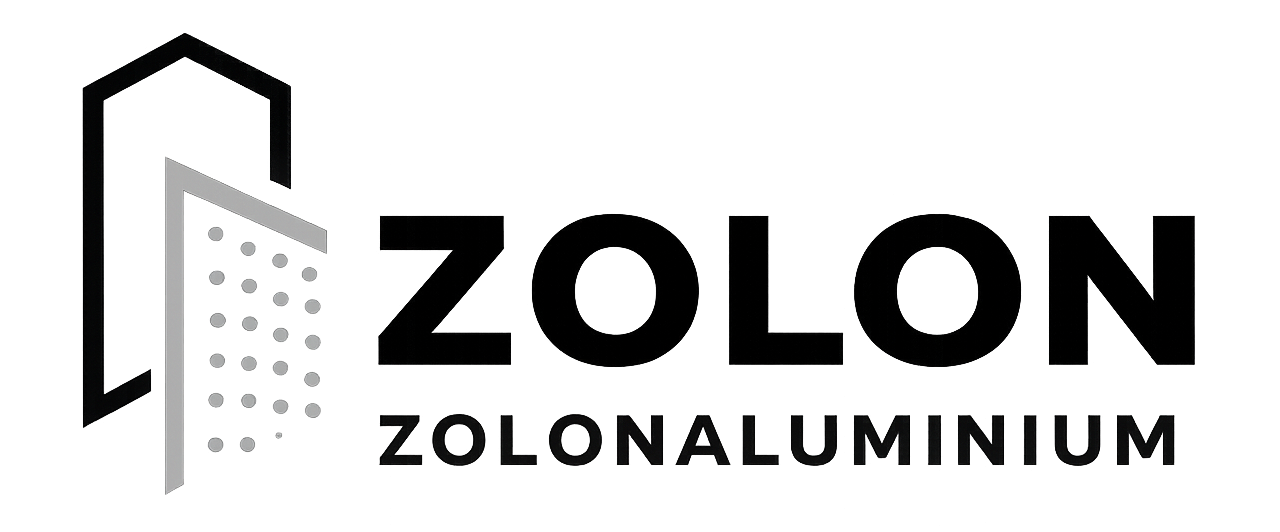

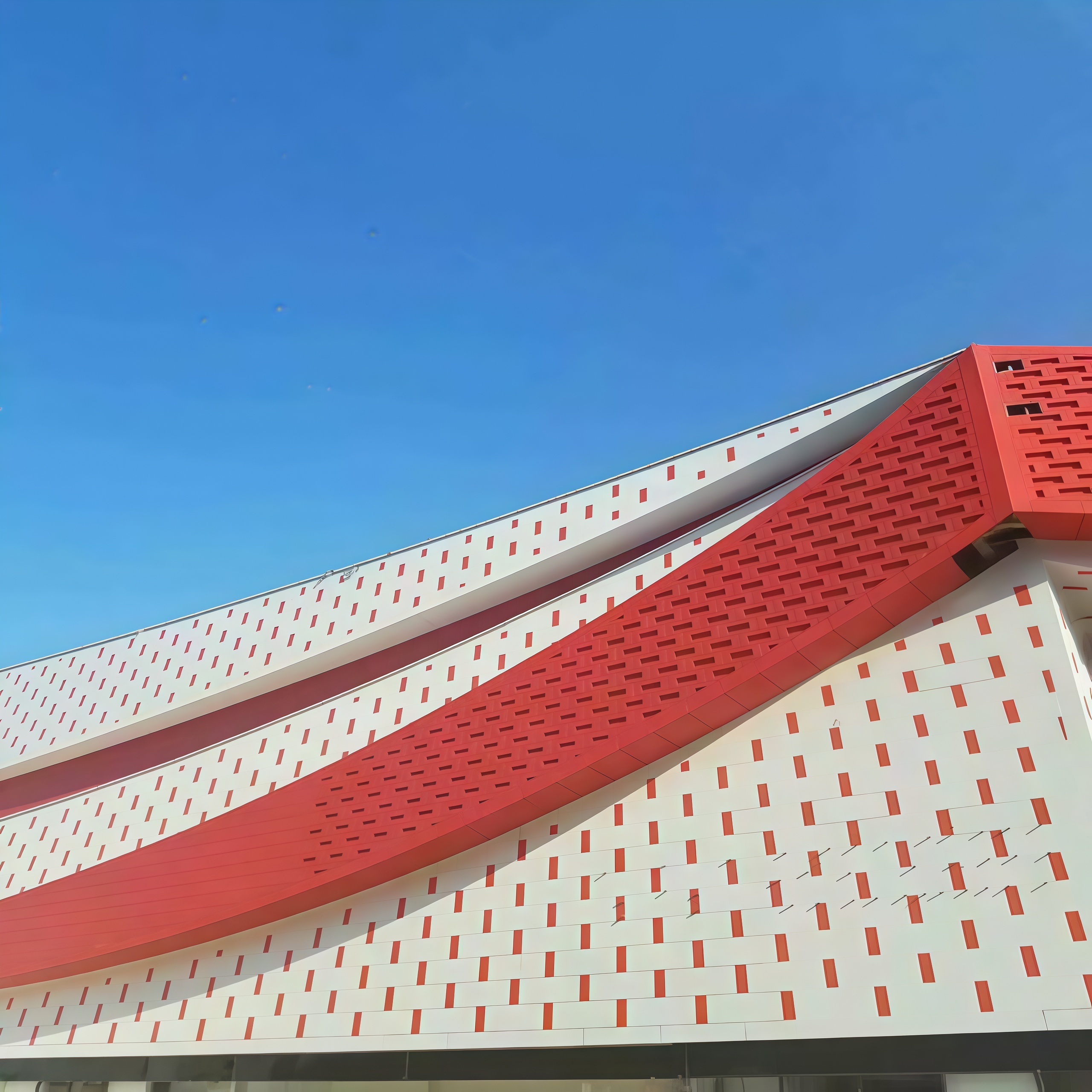

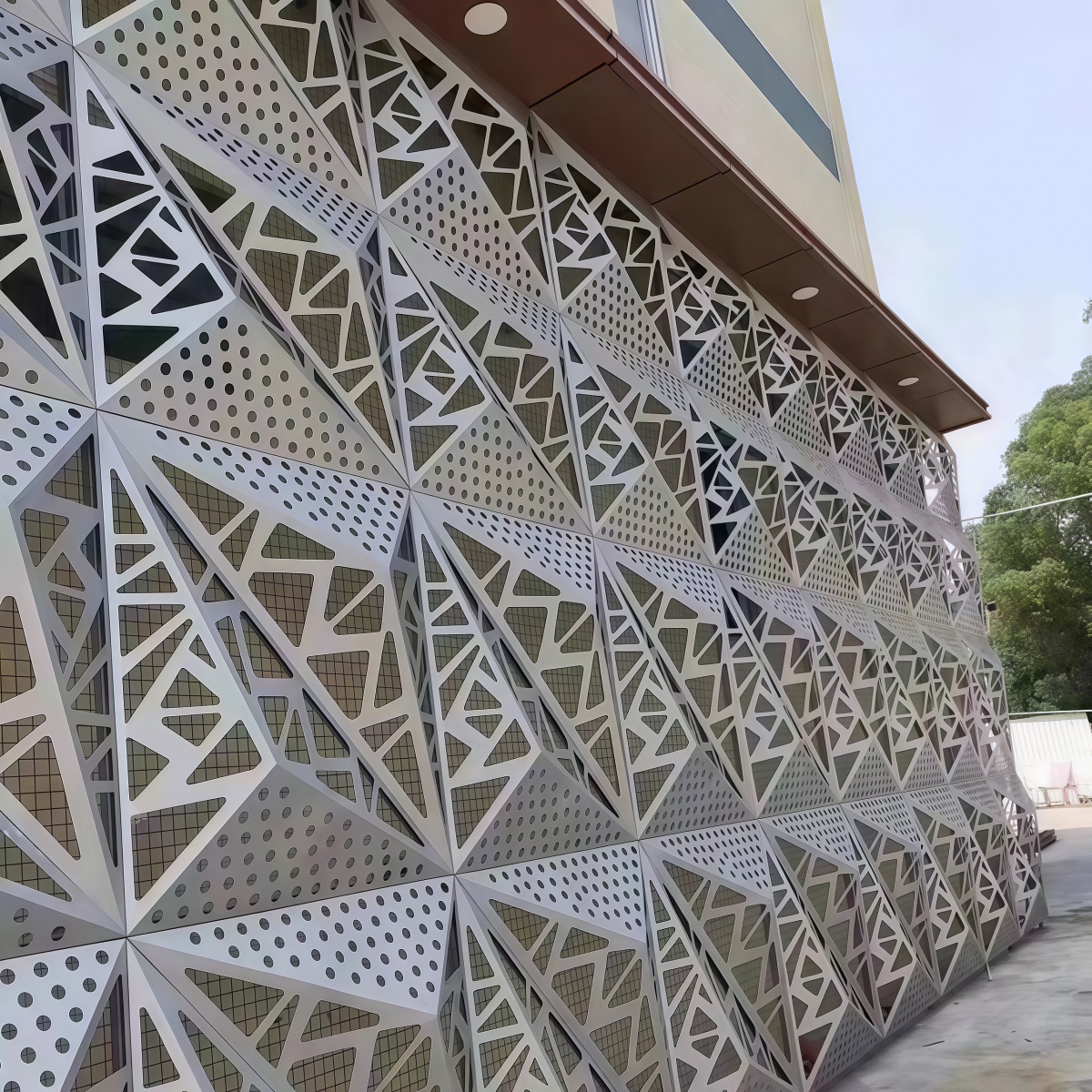

Double-curved panels are aluminum sheets formed into two-direction curvature, which allows architects to create elegant “wave”, “dome”, or “free-form” facade surfaces. Compared with flat panels, double-curved designs can achieve stronger visual impact, better continuity, and a premium architectural identity.

Typical applications

Landmark building facades and feature walls

Curved canopies, entrances, and soffits

Complex-shaped cladding for commercial and public projects

Section 2: Why 2.5mm + PVDF for Southeast Asia?

For Malaysia and Singapore projects, we recommend 2.5mm aluminum combined with PVDF coating for a balance of strength, flatness control, and exterior durability.

2.5mm thickness advantages

Better rigidity for curved surfaces

Reduced risk of oil-canning on large panels

More stable installation performance

PVDF coating advantages

Excellent UV resistance and color stability

Strong weather resistance in humid/coastal conditions

Easy maintenance and long service life

Section 3: Manufacturing & quality control

To deliver consistent double-curved geometry, fabrication accuracy is critical. We follow a controlled workflow from raw material to finished panel.

Key steps

Curve forming based on project drawings

Edge processing & reinforcing (if needed)

Surface treatment and PVDF coating

Trial fitting / inspection before shipment

What we check before delivery

Curvature accuracy and panel alignment

Coating appearance and color consistency

Packaging protection for safe transportation

Section 4: We support shop drawings & detailing

If you already have architectural intent drawings, we can support shop drawings, panel layout optimization, and detailing coordination.

Our support includes

Panel layout / joint suggestions

Fixing point planning and edge detailing

Coordination with sub-structure requirements

Production drawings confirmed before fabrication

This helps reduce site adjustment risk and ensures smooth installation scheduling.

Section 5: Installation system solution

For curved facades, reliable sub-structure and fixing logic are just as important as panel quality. We can propose a suitable installation system based on project conditions and design requirements.

We can provide

Matching installation accessories and fixing concept

System recommendations for different curvature and panel sizes

Technical support for contractor teams

Project focus: Malaysia & Singapore

We work with Southeast Asia clients who value fast response, stable lead time, and technical cooperation. If your project is in Malaysia or Singapore, you can send us drawings or facade intent, and we’ll help evaluate a practical solution.