Blog

Aluminum Great Wall Board: Fluted Cladding Panels For Walls And Ceilings

What Is An Aluminum Great Wall Board?

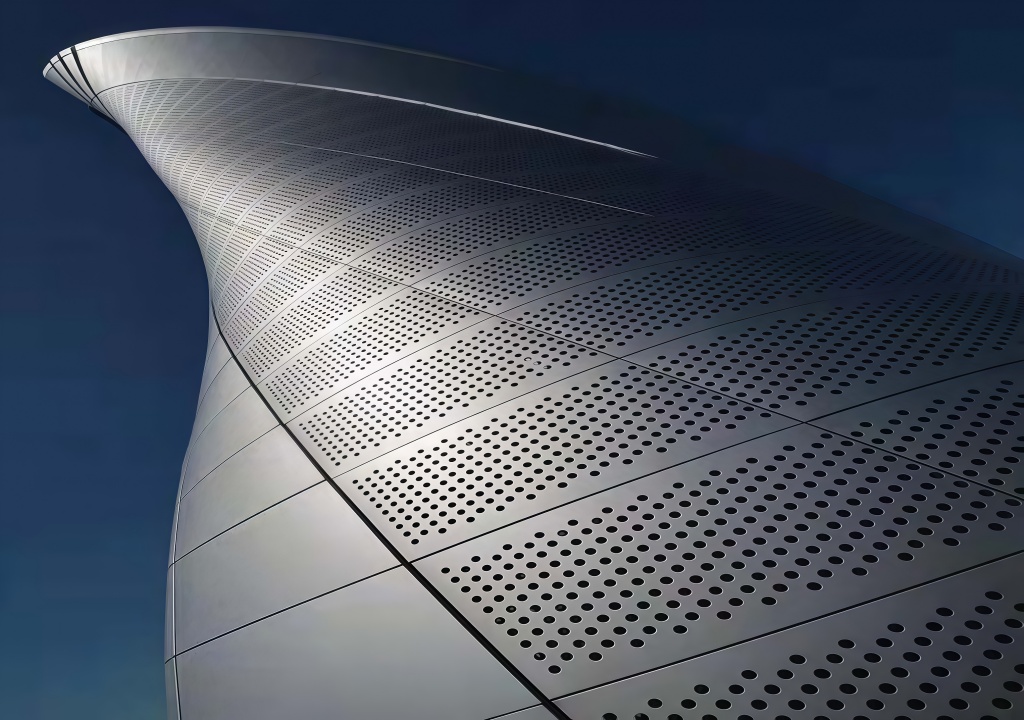

Fluted aluminum cladding profiles for modern wall and ceiling design.

Aluminum Great Wall Board is a fluted (ribbed) panel profile used to create strong linear aesthetics on facades, feature walls, soffits, and ceilings. It delivers a clean, architectural look while keeping the system lightweight, corrosion-resistant, and easy to maintain. Panels can be produced in customized lengths and modular sections for efficient transport and on-site assembly.

Why Architects Choose Great Wall Board Profiles

Designed for long-term durability with a premium finish.

Key advantages include: stable geometry, consistent shadow lines, and a modern “ribbed” texture that hides minor surface imperfections. Compared with heavier cladding materials, aluminum profiles reduce load and simplify installation. The system is suitable for both exterior and interior use with finish options matched to project requirements.

Finish Options For Visual Consistency And Weather Resistance

Multiple coatings and textures available for different design goals.

We offer common architectural finishes such as PVDF coating for exterior durability, powder coating for versatile color options, anodizing for metallic texture, and wood-grain finishes for warm, natural aesthetics. Custom colors can be matched by sample or color code to keep consistency across walls, ceilings, trims, and accessories.

Custom From Drawings + Complete Fixing System Support

From concept to shop drawings, fabrication, and installation guidance.

Send CAD/PDF drawings or a concept sketch with key dimensions and site conditions. We provide design detailing (panel layout, joints, trims), shop drawings for approval, production with QC checks, and a complete fixing solution (rails/brackets/fasteners) to make on-site work faster and cleaner. Segmented panels and hidden fixing options are available based on inspection and maintenance needs.

Aluminum Decorative Panels

Aluminum Great Wall Panels (also known as wavy panels / Great Wall board) create a strong 3D shadow-line effect for modern architectural surfaces. They are widely used as interior decorative panels, outdoor entrance/signage fascias, and exterior boundary wall cladding—where durability, clean detailing, and fast installation matter.

At ZOLON Aluminium, we support custom profiles from drawings, engineering detailing, and a complete installation system (subframe + brackets/fasteners), so your project can move from concept to site efficiently.

What Are Aluminum Great Wall (Wavy) Panels?

Great Wall panels are profiled aluminum decorative panels featuring continuous ribbed/wavy geometry. The shape increases visual depth and helps conceal minor substrate irregularities while keeping the facade or wall surface lightweight.

Key Benefits

Strong 3D texture and shadow-line aesthetics

Lightweight compared with many traditional cladding materials

Custom lengths and modular segmentation for transport & installation

Suitable for both indoor and outdoor architectural surfaces

Custom From Your Drawings (SEA / APAC Projects)

We support a clear design-to-production workflow for Great Wall / Wavy Panels:

Send Drawings / Concept: CAD/PDF + key dimensions (panel width/height, profile depth, joint concept, site conditions)

Engineering & Detailing: panel segmentation, fixing method, expansion joints, corner/edge solutions

Shop Drawings For Approval: we provide drawings for review before production

Production & QC: forming accuracy check, coating inspection, dimensional checks

Installation System: subframe/brackets/fasteners plan + on-site guidance if required

Core Specification (Recommended)

Because Great Wall panels are used in different scenarios, we typically recommend selecting thickness and coating based on application.

Panel Material

Aluminum alloy options: 3003 / 5052 (selection based on forming needs and project requirements)

Thickness (Typical Selection)

Interior decorative panels: 1.0–2.0 mm

Outdoor fascia / signage / boundary walls: 2.0–3.0 mm (project-dependent)

Surface Finish Options

PVDF Coating (recommended for outdoor durability)

Powder Coating (common for interior & semi-exterior)

Optional: anodized / wood-grain / stone-like finishes (project-dependent)

Manufacturing & Quality Control

Great Wall geometry requires consistent forming to keep the shadow lines clean and continuous. We follow controlled steps from raw material to finished panels.

Key Steps

Profile forming based on approved shop drawings

Edge processing & reinforcement (if required)

Surface pretreatment and coating process control

Trial fitting / inspection before shipment

What We Check Before Delivery

Profile consistency and straightness

Dimensional tolerance (length/width/profile depth)

Coating appearance & thickness inspection

Packaging protection for long-distance transport

Typical Applications

Interior Decorative Panels (feature walls, lobby walls, retail interiors)

Outdoor Entrance Fascia & Signage (storefront headers, canopy fascia, branding zones)

Exterior Boundary Walls (perimeter walls, privacy screens, architectural fences)

Installation System & Site Efficiency

A well-designed subframe improves installation speed, alignment, and long-term stability.

Installation Highlights

Hidden fixing solutions for a clean surface

Adjustable bracket system for tolerance control

Segmented panels for easy transport and on-site assembly

Optional access solutions where maintenance is required

Download Our Catalog & Technical Support

Get Great Wall Board profile options, finish references, and typical fixing details.

Go to Download Page: /download/

WhatsApp: +86 15818816468

Email: info@zolonaluminium.com