Blog

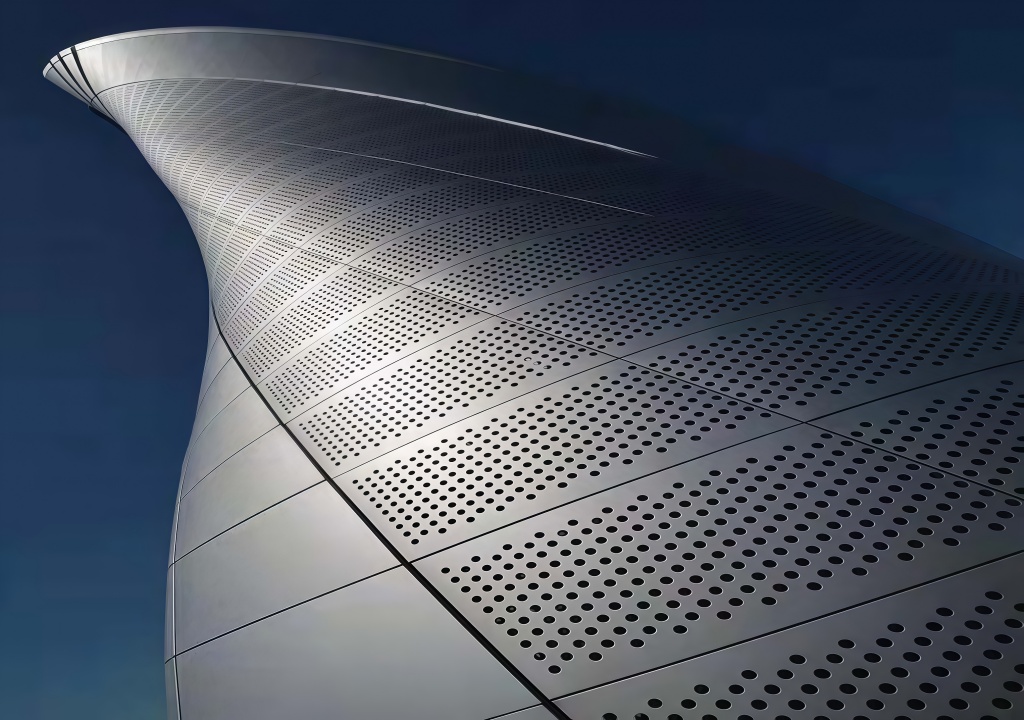

Perforated Aluminum Panels for Facades & Ceilings: 2.5mm PVDF, Custom Patterns & Installation System

Perforated Aluminum Panels for Facades & Ceilings (2.5mm PVDF)

Perforated aluminum panels are widely used for building facades, ceilings, screening, and feature walls—offering ventilation, daylight control, and a modern architectural appearance. At Zolon Aluminum, we supply 2.5mm perforated panels with PVDF coating, tailored for Malaysia and Singapore projects, with full support from drawing-based detailing to installation system solutions.

Why Architects Choose Perforated Panels

1) Light & ventilation control

Perforation patterns help balance shading, airflow, and visibility—ideal for tropical climates.

2) Custom design & branding

From round holes to slotted and bespoke patterns, we can match your design language and create signature building identity.

3) Durable outdoor finish

Our standard recommendation for exterior use is PVDF coating, which provides strong weather resistance and long-term color stability.

Our Recommended Specification

For most facade/screening applications, we suggest:

Material: Aluminum alloy (project-based)

Thickness: 2.5mm (popular choice for facade screening & feature applications)

Surface finish: PVDF coating for exterior durability

Perforation: standard patterns or custom patterns based on drawings

Fabrication: cutting, perforation, forming/bending, reinforcement (if required)

Packing: export-standard protection for long-distance delivery

If your project has wind load or span requirements, we’ll recommend reinforcement methods and edge details accordingly.

Engineering Support: Drawing-Based Detailing

We support clients who need more than just materials. If you provide a concept drawing, we can help with:

Pattern layout confirmation & optimization

Panel joint / edge / return details

Subframe logic suggestions (project-based)

Quantity take-off assistance (based on drawings)

This is especially helpful for contractors and facade specialists in Malaysia and Singapore who need practical detailing for site installation.

Installation System Options

Depending on your project goals (budget, speed, maintenance access), we can propose suitable fixing methods, such as:

Concealed fixing for clean facade appearance

Accessible fixing for easier maintenance

Project-based subframe suggestions (subject to final drawings and site conditions)

If you already have a preferred system, we can adapt the panel fabrication to match it.

Typical Applications

Facade screening & sunshade

Ceiling panels & soffits

Feature walls & decorative cladding

Ventilation screens & equipment enclosures

Stairwell / balcony / railing infill panels

FAQ (Quick Answers)

Q1: Is 2.5mm enough for exterior perforated panels?

For many facade screening and feature applications, 2.5mm is a common choice. Final thickness and reinforcement depend on panel size, span, wind load, and fixing method.

Q2: Why PVDF for outdoor use?

PVDF coating is widely used for exterior aluminum panels because of its weather resistance and long-term color stability.

Q3: Can you make custom patterns?

Yes. We can produce perforation patterns based on your CAD/drawings and help you confirm pattern layout for the best visual effect.

✅ Download Our Catalog (Perforated Panels)

Want full specifications, finish options, and reference projects?

Click below to download our catalog & factory profile.

(Email required — we’ll send the download link to your inbox.)

👉 Download Catalog: https://zolonaluminium.com/download/

Nanhai, Foshan, Guangdong, China