Blog

Aluminum Facade Panels: Materials, Finishes, and What Buyers Should Ask Before Ordering

Zolon Aluminum provides OEM/ODM aluminum facade solutions — from drawings to mass production, with strict QC and export-standard packaging.

Aluminum facade panels are widely used for commercial buildings, public projects, and architectural interiors.

But for buyers, the “right” panel is not only about appearance — it affects durability, lead time, installation, and total project cost. In this article, we’ll share practical points that help you select the correct material, finish, and fabrication approach.

1. Common Panel Types and Applications

Aluminum veneer / cladding panels

Ideal for building facades, feature walls, and large-area exterior surfaces

Lightweight, corrosion-resistant, easy to fabricate into complex shapes

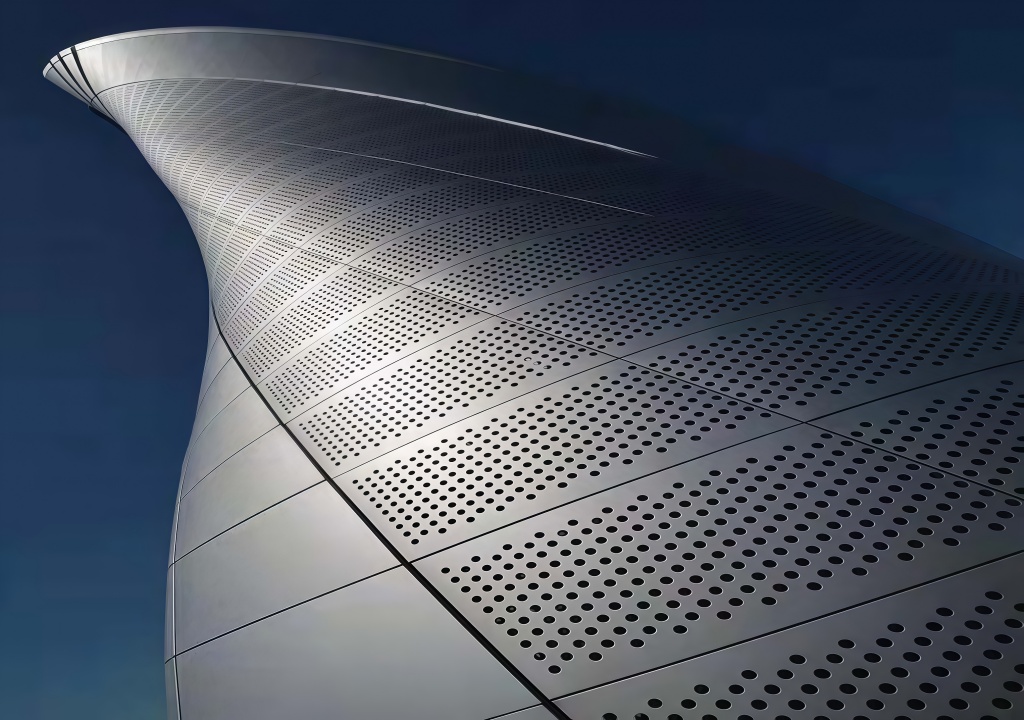

Perforated aluminum panels

Used for sun-shading, privacy screens, ventilation, and artistic facades

Custom perforation patterns available for branding and design concepts

Aluminum louvers & grilles

Suitable for HVAC covers, ventilation facades, and decorative screening

Designed for airflow while keeping a clean architectural look

Aluminum ceiling panels

Common for airports, malls, stations, and commercial interiors

Stable, easy to maintain, with consistent visual performance

2. Material Options: What to Confirm

When you request a quotation, confirm these key specs:

Alloy & temper (example: 3003 / 5052)

Panel thickness (commonly 2.0mm / 2.5mm / 3.0mm)

Panel size (width/height) and tolerance

Reinforcement requirements (stiffeners, ribs)

Installation system (cassette / tray / framed / concealed fixing)

These details directly impact strength, flatness, and installation efficiency.

3. Surface Finishes and Performance

Your project environment decides which finish is best:

PVDF coating (recommended for exterior)

Excellent weather resistance and long-term color stability

Suitable for harsh outdoor conditions

Powder coating (cost-effective, interior/exterior depending on spec)

Wide color selection, good durability

Confirm outdoor-grade powder if used externally

Anodizing / wood-grain / stone-grain effects

Premium aesthetics for high-end architectural projects

Best used with clear design targets and sample approval

Tip: Always request color samples or approval panels before mass production.

4. From Drawing to Delivery: Typical Production Workflow

A reliable supplier usually follows:

Drawing review (CAD / PDF / 3D files)

Engineering confirmation (bending radius, joints, installation method)

Sample / mock-up approval (optional but recommended)

Mass production with strict QC (dimension, coating thickness, appearance)

Export-standard packaging to reduce damage in transit

Shipping & after-sales support

If your project has a tight schedule, share your target delivery date early — it helps optimize production planning.

5. Buyer Checklist (Fast Quotation)

To get an accurate quote quickly, send:

Product type (facade panel / perforated / louver / ceiling / grille)

Drawings or sizes + quantity

Finish requirement + color code

Project location (for climate reference)

Expected lead time and shipping terms

Ready to Discuss Your Project?

If you have drawings or requirements, our team can provide fast evaluation and recommendations.

Send your drawings and get a solution within 24 hours.

👉 Contact: WhatsApp: +86 15818816468

👉 Email: info@zolonaluminium.com